Playing with Legos as a kid is merely a precursor to the world of assembling parts into custom fabricated components. Think about it for a moment. There are hundreds of different sizes and shapes of Lego blocks. Some are very basic like a standard four stuff by two stud Lego block. Others are more intricate like specialty pieces for themed sets. The same is true when it comes to assembly in the world of custom fabrication. Each custom part we make at IMH Products, when you break it down, is assembled from other, smaller parts.

The Teamwork of Assembly in Fabrication

The process of assembly requires multiple teams to be on the same page. When the customer comes to a fabricator like IMH Products with a design it is up to our engineers to develop the assembly process. This can include some or all of the following: computer modeling, cutting, shearing, punching, laser technology, forming, hardware insertion, spot welding, welding, and more.

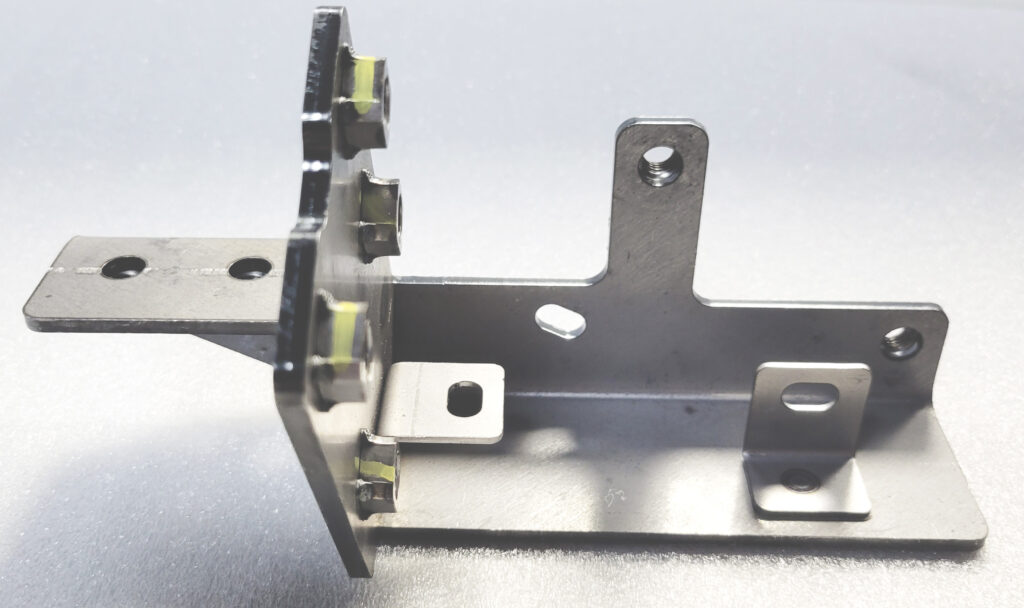

Once a design is complete, the real magic of the operation happens. Individual components are then fabricated using the necessary methods. Sometimes this involves the folding or pressing of sheet metal. Other times it can be laser cutting or punching. The pieces then come together in the assembly area, where welding, riveting, threaded fasteners, and even adhesives bring the individual components together.

Fabrication and assembly are two activities that often coincide with each other. In most processes both human labor and automation are involved. Automation alone can handle much of the process and make it more efficient, but there is often still a human element even if it is the final step of quality control. IMH Products utilizes multiple spot checks throughout the process of assembly to assure that every step is followed accurately.

Finishing the Process

The final assembly of components that involve multiple parts is only part of the process. Once that is done, many components need finishing services such as anodizing, e-coating, galvanizing, heat treating, or other coatings. IMH coordinates the entire fabrication process, facilitating machining operations and vendor relationships for our partners.

Finishing services both optimize the machinability of parts and increases their aesthetic appeal. That’s why IMH leverages our capabilities and relationships to provide anodizing, e-coating, galvanizing, heat treating, military coating, powder coating, and silk screening services for a diverse range of materials and applications.

What makes IMH Products stand out is our ability to do custom fabrications all under one roof. To make the process sound simplistic, we can bring in something as simple as a sheet of metal and by the time it leaves our shop it can be an intricately cut, folded, welded, and finished part that is ready to be installed for whatever application our partners need. We are also constantly refining our fabrication process to increase efficiency and lower the costs for our clients. That is why we have invested in the latest design technology, mills, lathes, welding cells, and more so we can control the entire process from start to finish.

Let us partner with you so we can deliver the results and parts you need. Contact us at sales@imh.com